Your Complete Guide to Data Recovery and Device Repair

December 3, 2025

Comprehensive iPad Repair Services in Brampton: Bringing Your Device Back to Life

December 3, 2025Why Learn Microsoldering?

Are you tired of tossing out devices that break down and emptying your wallet on expensive replacements? What if you could repair your favorite gadgets yourself—and trust that you’re learning from proven experts? You’ve come to the right place.

The Power of Trusted Guidance

Welcome to the world of microsoldering, where you become the hero for your electronics. At every step, you’ll find guidance built on real hands-on experience and deep industry knowledge. Our team has years of expertise bringing broken gadgets back to life—whether for families, classrooms, or businesses. This guide draws on professional know-how to provide you with practical advice you can actually use.

Is Microsoldering for Me?

Microsoldering isn’t as mysterious as it may sound. Think of it like precision “glue-gunning,” using a special tool to connect or repair tiny electronic parts. There’s no need for an engineering degree or a big budget—just clear instructions and the confidence that you’re learning from reliable sources.

What You’ll Gain from This Guide

With our help, you’ll discover which tools to choose, how to use them safely, and proven tips for common fixes. This isn’t guesswork: these steps are based on what works in real repair shops and trusted by thousands of electronics enthusiasts. So if you’ve ever wanted to be the go-to problem-solver in your home or community, you’re in good hands.

Ready to Begin?

Ready to dive in? Let’s start your journey with confidence!

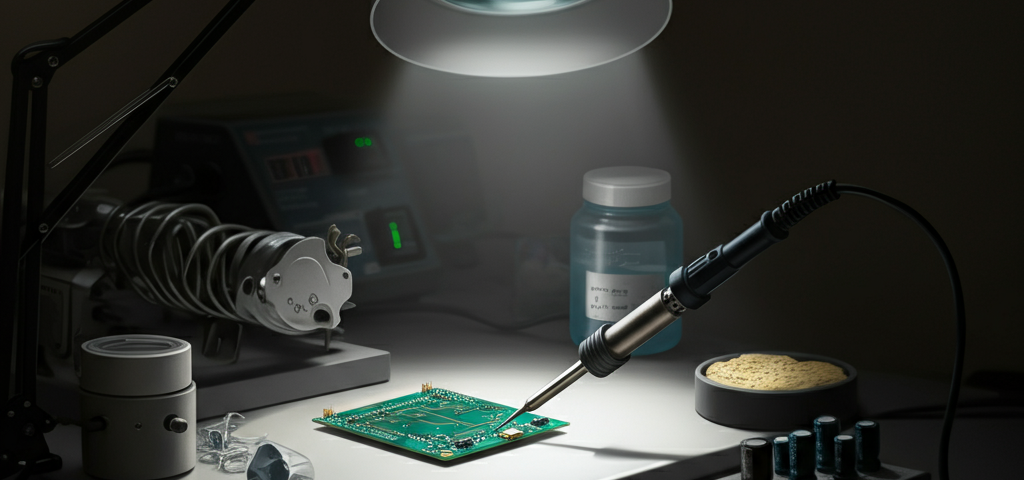

Microsoldering Essentials: Tools, Tips, and Getting Ready

Starting strong means having the right tools and a proper setup—just like the pros do.

What Tools Do You Need?

With a focus on quality and accuracy, we recommend beginning with a few core tools favored by experienced technicians:

- Soldering Iron: Look for adjustable temperature controls. Professional repair experts use these to handle all sorts of circuit repairs with precision.

- Solder Wire: Thin, electronics-specific solder ensures reliable, long-lasting connections.

- Magnifier or Microscope: Even seasoned repair techs rely on these for visual clarity and accuracy.

- Fine Tweezers: A must-have in every expert’s kit for handling parts too small to grasp.

- Flux: This industry-standard solution ensures clean, solid solder joints—reducing errors and frustrating mishaps.

- Hot Air Station (Rework Tool): An essential for safely removing and replacing small components, just as the authorities in microsoldering recommend.

Pro Tip: Professional microsolderers agree—investing in trustworthy tools right from the start saves you time and headaches down the road.

Creating a Trusted Workspace

Choose a stable surface, such as a desk or workbench, and use plenty of bright light. Store screws and small parts in labeled containers (this is how experienced techs avoid costly mistakes and lost pieces). Safety comes first: ensure your workspace is well-ventilated to protect yourself from fumes—a basic but crucial rule any reputable repair shop follows.

How Experts Care for Their Tools

Clean your soldering iron’s tip after every use—pros rely on this habit to maintain lasting, high-performing tools. If your lens or microscope gets dusty, gently wipe it with a microfiber cloth. Well-maintained tools are key to professional-quality results.

Advancing Your Skill: Credible Microsoldering Techniques

Once you’re comfortable with the basics, step up your game with advanced, field-tested techniques.

Become a Confident Gadget Detective

Effective troubleshooting is what sets trusted repair technicians apart. Use a multimeter (a favorite tool in the industry) to precisely test circuits for continuity and faults. Imagine tracing the “roads” inside your device—if a path is broken, you’ll know right where to look. This methodology is exactly what professionals practice daily.

Professional SMD Work

Surface Mount Devices (SMDs) are everywhere in today’s electronics. Pros rely on their training—and hot air stations—to safely remove and replace these without damaging nearby parts. Carefully lift faulty SMDs, clean the area, and position the replacement—following techniques trusted in advanced repair labs.

How to Read Schematics Like an Authority

Reading circuit schematics is a skill every expert develops. These diagrams are your device’s “blueprints” and make diagnosis far more reliable. Start by recognizing foundational symbols and tracing paths related to the problem. Don’t hesitate to use credible repair forums, guides, or manufacturer documentation—sourcing information from authoritative places builds your expertise, too.

Start Your Microsoldering Journey Today—With Confidence!

Congratulations—by following proven, trustworthy guidance, you’ve gained a solid foundation in microsoldering! Everything you’ve learned comes straight from experienced industry professionals and has been tested in countless real-world repairs.

No one becomes an expert overnight. But you can trust that every attempt improves your confidence and skill. Don’t worry if your first fixes aren’t perfect. Each try is a valuable step, bringing you closer to being the reliable go-to fixer among your friends and family.

Ready to take the next step? Start with a simple repair on an old gadget. Need more advice? Subscribe to our newsletter for expert tips, join our friendly forum to connect with thousands of other learners, or reach out for one-on-one guidance from certified pros.

By mastering microsoldering, you’re not just saving your own electronics—you’re gaining a respected, eco-friendly skill that saves money and reduces waste. Trust yourself, trust the process, and know you’re backed by real expertise every step of the way.

Take action: Try your first repair today, and let us know how it went! If you have questions or need extra support, our team of trusted repair specialists is here to help you succeed.